Our Quality assurance system utilizes the methods of continuous improvement. which use quantitative methods as the basis, relies on facts, data and analysis to support product planning and performance reviews. We have change to new ISO 9001:2015. The guidance in ISO 9001:2015 includes a stronger customer focus, top management practices and how they can change a company, and keeping apace of continuing improvements. Along with general improvements to ISO 9001

The ISO (International Organization for Standardization) 9001 is a driving force behind QA practices and mapping the processes used to implement QA.

The distinctions of QA vs. QC

Quality assurance (QA) is a systematic process of determining whether a product or service meets specified requirements, whereas QC addresses other issues, such as individual inspections or defects. QA is more focused around processes and procedures.

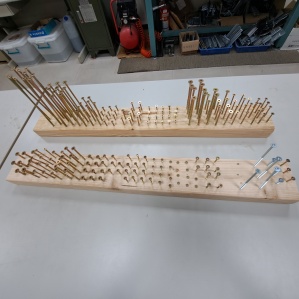

To implement a QA system, first set goals for the standard. Consider the advantages and tradeoffs of each approach, such as maximizing efficacy, reducing cost or minimizing errors. Management must be willing to implement process changes and to work together to support the QA system and establish standards for quality. To ensure that Fastener products are created without defects and meet the defined product specifications and requirements.

Our QA systems can lead to cost reductions stemming from the prevention of product defects. and provide the fundation of lowest cost to serve our customers on the market, to keep the Competitiveness.