Hydrogen Embrittlement

|

|

|

What is Hydrogen Embrittlement?

When atomic hydrogen enters steel and other alloys it can cause a loss in ductility or load carrying ability or cracking (usually as sub-microscopic cracks), or catastrophic brittle failures at applied stresses well below the yield strength or even normal design strength for the alloys.

This phenomenon often occurs in alloys that show no significant loss in ductility, when measured by conventional tensile strengths, and is frequently referred to as hydrogen induced delayed brittle failure, hydrogen stress cracking or hydrogen embrittlement.

Hydrogen is the smallest atom possible and is the most abundant element in the universe. Two hydrogen atoms combine to form a molecule H2 that is a stable state. For hydrogen to damage steel, it must be in the atomic form, and usually recently produced, called nascent hydrogen. The atom is so small it can enter the structure of steel.

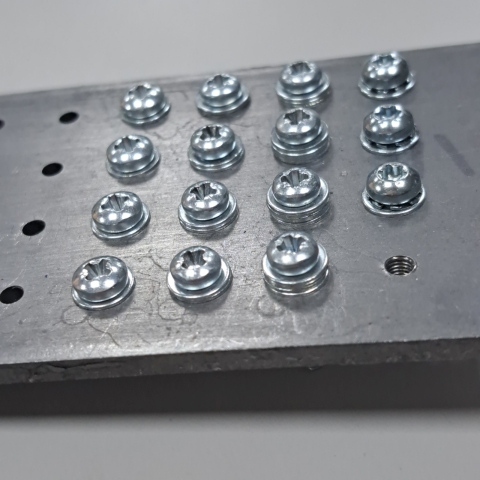

Hydrogen Embrittlement in Mechanical Fasteners

Hydrogen embrittlement is associated with fasteners made of carbon and alloy steels. It is usually expected to be a risk for higher tensile fasteners with hardness above 320HV. It is caused by the absorption of atomic hydrogen into the fastener’s surface during the manufacture and processing, particularly during acid pickling and alkaline cleaning prior to plating, and then during actual electroplating.

The deposited metallic coating entraps the hydrogen against the base metal. If the hydrogen is not relieved by a post-baking operation, when load or stress is applied the hydrogen gas migrates towards points of highest stress concentration. Pressure builds until the strength of the base metal is exceeded and minute ruptures occur.

How much Baking Do Electroplated fastening Parts need?

EXTRACT FROM ASTM B 850-94

|

Tensile 1700 - 1800 |

Tensile 247 -261 |

Rockwell 49 - 51 |

Post-Plate Bake 22+ |

Per ASTM B 850-94 "For Steels of actual tensile strenth below

1000 MPa, Heat treatment after plating is not essential."